October 19, 2023

New Twist on Wrenches

We cannot do without fasteners to hold things together and fasteners must be turned with wrenches. Wrenches do not appear to have changed much in 50 years, but fasteners certainly have. Most fasteners used to be made with steel with an ultimate strength of 60,000 psi. Today, 180,000 psi is common. And still, higher-strength fasteners are used for some aerospace applications. The small head 12-point fasteners double the load on the wrench. Combine these, and there is a six-fold increase of load on the wrench. And we wonder why wrenches sometimes fail.

Early wrench manufacturers did not have CAD-CAM or elaborate testing machines, so they often over designed the wrenches to ensure that they performed well. For example, this meant thicker walls and larger nut end diameters for sockets. Machinery manufacturers used these dimensions to provide wrenching clearances. The pressure was on wrench manufacturers to stay within the traditional sizes. Wrench manufacturers responded with better material and better heat treatment processes. High-quality wrenches are made to tighter tolerances now, but as they wear, their strength decreases, so a wrench that is badly worn can knock the corners off a fastener, which makes the wrench/fastener torque transmission even less.

Of course, the biggest problem for users is not in the assembly of wrenches or the fasteners. Modern engineering calls for tightening torques to be measured to make sure that there is both enough tension in the fastener to carry the required load and not so much tension that the fastener will break from fatigue or will be difficult or even impossible to remove. Removal torque is often twice the installation torque, so if a fastener has been overtightened, its removal can be particularly difficult.

How to Get Stronger Wrenches That Last Longer

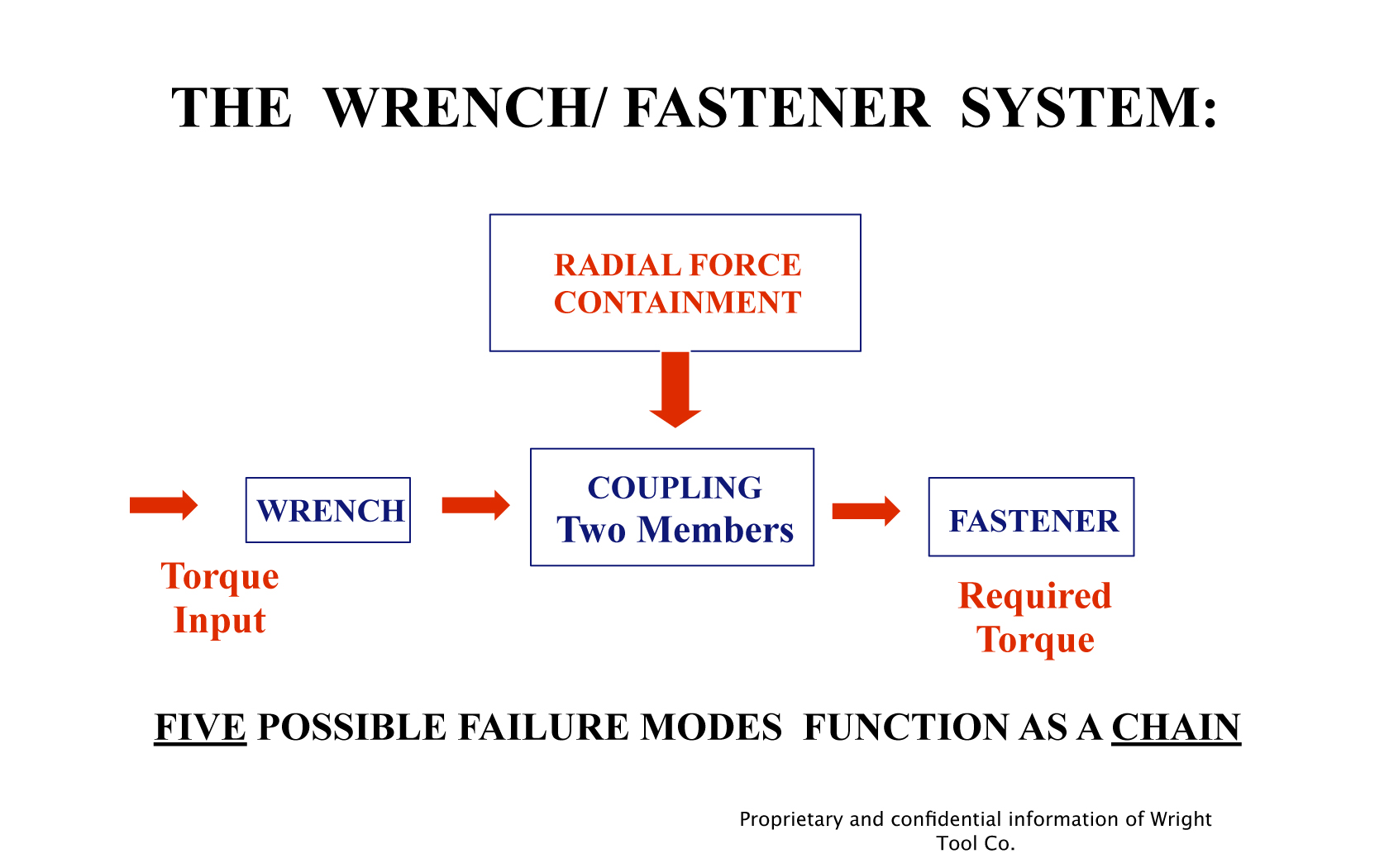

Think of the wrench and fastener head as a coupling that transmits torque from user to the wrench of a fastener (see Diagram). How well this coupling works depends on the nature of the wrench, the nature of the fastener, and how well they fit together. The first thing a user should do is inspect the wrench that is going to be used to make sure it is not too worn or cracked from previous use. As indicated above, there is a tendency to overload wrenches; this can result in immediate breakage or produce a crack which can lead to injury later. Next, the user should know what grade of fastener is to be tightened. Extra care should be used on high-strength fasteners. The strongest type of wrench is a socket wrench. Most sizes are made in three different drives and the safest drive is always the largest drive, especially if a high-strength fastener is involved. The smallest drive should be used only when the space does not permit a larger wrench. Impact guns not only produce more torque more easily, but also a fastener can be turned at a higher torque by a series of blows than by a steady pull. Only black sockets made for impact use should be used on impact guns. For large fasteners, slugging wrenches are an alternative.

Wright Drive and Wright Grip 2.0

Wright has improved wrench opening designs to make a better distribution of forces between the wrench and the fastener. Wright’s proprietary designs for both six-point and 12-point sockets and its design for the open-end of combination wrenches deliver substantially more torque with less damage to the corners of the fastener.

Wrench/Fastener Choices

In the design of machinery, one should use fasteners of ample strength, not only for the performance of the machine, but to allow for their removal and replacement without trouble. Damaged fasteners should always be replaced with new fasteners. High strength fasteners should never be reused, and it’s a good idea to replace any fastener that is worn.

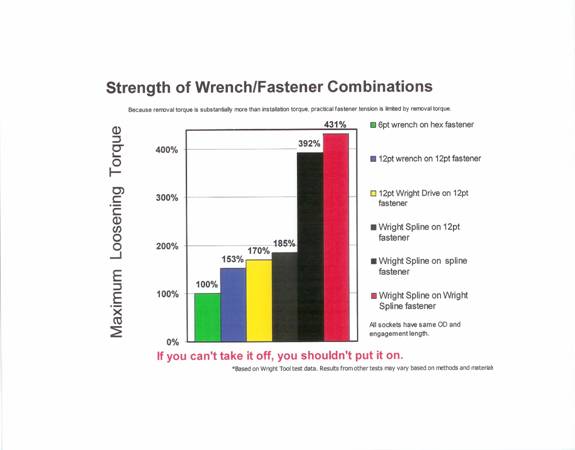

The accompanying graph shows the maximum strength that can be transmitted to the fastener with different combinations of wrenches and fasteners. The outside diameter of the wrench is the same for all examples as is the size of the fastener. The difference is in the design of the engaging surfaces and the materials from which the wrenches and fasteners are made.

Over time, fasteners have evolved, so it’s important to keep up-to-date on fasteners and wrenches. This allows you to know common issues and know how to have a wrench last longer on the job.